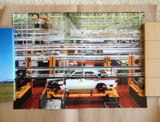

Wow. Nearly camouflaged.

While each pool has a pumping system powerful enough to recycle 52,000 gallons of water per minute, it is the surface of the nearly 1,600 lineal ft of parapets that had to be robust enough to withstand rain, scorching heat, snow and ice as well as the wear and tear of three million annual visitors. For the comfort of the millions of hands that will touch the etchings, the parapets have a heating and cooling system.9/11 Memorial Is Centerpiece of World Trade Center Redevelopment [enr via @chton1c]"The [National September 11 Memorial & Museum non-profit foundation] was very concerned about making the experience as pleasurable as possible for visitors," many of whom will want to touch the engraved names, says Robert Downward, an associate with the project's local MEP engineer, Jaros Baum & Bolles.

JBB and Service Metal Fabricating, the parapet's Rockaway, N.J.-based supplier, knew of no prototype for a project like this, so they started from scratch to build a back-mounted tubing system that would work within the parapets and the nameplate system. The fabricator built a prototype of the panel, tested it under sunlight and then analyzed the results using computational fluid dynamics modeling.

"We calibrated the model so that it produced results in line with real field conditions," Downward says.

The result is a network of tubes that feed water behind the bronze plates. The tubes, nearly camouflaged, are underneath the plates and parallel to the rows of names.

"The spacing between the tubes was critical to maintaining comfortable temperatures at the panel surface," Downward says.

Each parapet section was shipped to the site with the tubes attached. Then, using a series of manifolds, workers connected the tube sections to the piping. The piping is connected to below-grade equipment that supplies the heated or chilled water.