An update on the Enzo Mari x Ikea autoprogettazione table project:

I just finished putting on the second coat of varnish sealer, and now everything’s drying and curing in the basement. The picture above was how the wood sat for a week between the first coat and this morning, stacked on our radiator [I moved it up after about 24 hours when it wasn’t quite cured, and then my schedule got away from me for the week.]

I’m sure it’s toxic and flammable and what not, but the tung oil varnish is a real, easy pleasure to work with. Goes on and off really nicely. Anyone who’s made something from wood probably knows this already, but the gradual surface and finish improvements brought on by each step of the sand-vacuum-tack-apply-sit-wipe-dry-cure cycle are fascinating to see. And you start to realize how most modern furniture is really just an industrialized approximation of what is only rarely done by hand. It’s like living in a world of Miracle Whip and never knowing there’s a thing called mayonnaise.

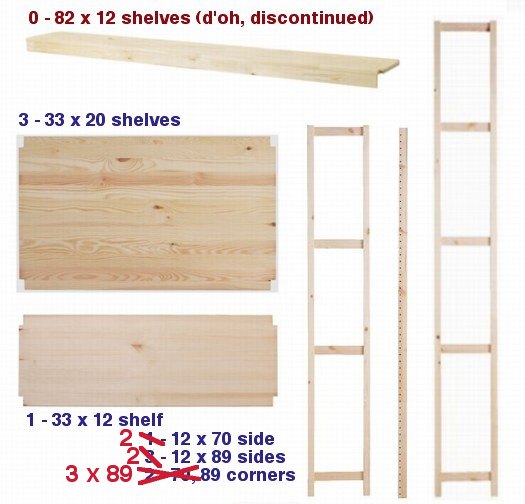

Another couple of observations: Ikea’s wood is really crappy, but some wood is much crappier than others. The Ivar corner posts feel denser and stronger than the sides, for example, and make me glad I decided to use them for the table legs. All these long pieces of wood are engineered, made up of several short pieces, spliced together. The shelves are the crappiest of all, all glued up strips of varying quality, which made it really hard to find relatively clear, relatively straight pieces.

Mari’s original instructions for the autoprogettazione furniture was to leave it completely unfinished and unsanded. And that would have taken a hell of a lot less time, work, and money. I expect the majority of buyers of Ikea’s unfinished Ivar shelving system leave it as is, too, opting for cheapness and speed over a finish they just don’t care about. Which means that assuming they don’t think it’s “wasted” completely, to most people, all the extra effort to finish what is really low-grade wood will be unappreciated, uninteresting, unwanted, or unnoticed. It’s better than lipstick on a pig, but it’s pointed in that direction.

Some changes mid-course to the design:

I don’t know how I missed this during the months of calculating, recalculating, staring, checking, and shopping, but 1 3/4 inches is not the same as 1 5/8 inches. It’s 1/8 of an inch different. Can you believe that?

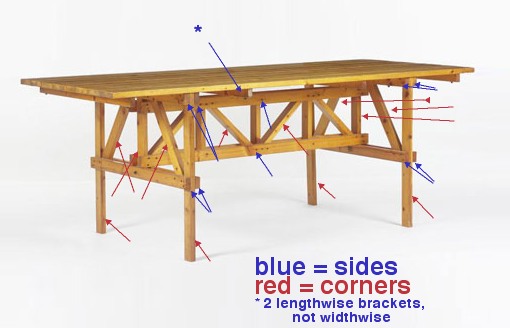

This revelation only occurred to me when I started piecing the trusses together, just to see how they’d go. All the diagonals above were originally made from the ladder-shaped, 1 3/4-in. bookcase sides, while the legs and the verticals were from the square, 1 5/8-in corner posts. But the diagonals, then, were too wide, and the trusses wouldn’t lay flat. The diagram above shows which pieces need to be square corner wood, and which need to be side wood.

The only solution was to head off to Ikea and buy enough corner post [6×18 inches, basically] to make all the diagonals. This altered the minimum/optimum number of Ivar parts that are required to build the table: basically, you could get two shorter sides and two taller sides, and then three long corners. Here’s the revised parts list:

The new parts total cost:

4 – Ivar shelf sides: 2 x $15, 2 x $20 = $70

3 – Ivar corner posts: 3 x $15 = $45

4 – Ivar shelves: 3 x $15, 1 x $7.50 = $52.50

subtotal: $167.50.

Finish:

2 pints, tung oil varnish: $85 or so

12 sheets, sandpaper: $8

tack cloth: $4

latex gloves: $4

Assembly:

Nails: $5

Wood glue: $4

clamps: $16

So right now, we’re looking at $293.50, more expensive than all but a couple of the comparably sized dining tables at Ikea, and almost the exact same price [$299] as the Forsby, made from finished solid pine. In the years since 1974, when Mari and Ikea both launched concepts for low-cost design for the everyman, it appears Ikea has lapped autoprogettazione more than a few times.