Once again, I’m getting burned for procrastinating on a project. And once again, I’m forced to reckon with how susceptible we are to the illusion a company can create of cultural stability and reliability, even as it constantly effects changes that suit its own business purposes.

Which is a lot to pile onto a tiny, cheap-ass Ikea Lack side table. Even before I finished my Ikea X Enzo Mari autoprogettazione table in 2009, I had the idea of making another one.

For the first, I’d found the single Ikea product that felt closest to the original lumber Mari specified for his designs: the unfinished pine components of the Ivar shelving system.

I wanted to realize the second table, though, in the product that felt the most Ikea: the Lack table. The Lack collection is pure Ikea: high modern, highly engineered, and super-cheap. The Lack is a marvel of perfect crappiness: sawdust legs and honeycomb cardboard tops encased in a structural plastic shell. You can’t cut a Lack without destroying it, but the series’ tables and shelves all share proportional dimensions, so it’s possible to tile them together.

my favorite Lack reference: MVRDV’s 2007 proposal for the Boijmans von Beuningen Museum Depot in Rotterdam. Alas, unbuilt.

The other day when Man Bartlett posted on his tumblr about visiting Brent Birnbaum’s studio, this awesome image made my heart leap–off the Ikea ferry, and then to promptly sink into the East River.

On the wall of Birnbaum’s studio is a piece called Untitled (Ikea), which is assembled from a veritable rainbow of Lack tables and shelves the artist has collected around town. It’s like, “WHOA, DOUBLE RAINBOW!” And exactly the patchworked minimalist look I was hoping for.

And the killer thing is, when I came up with the idea 2+ years ago, there was a literal rainbow of Lack side tables stacked in a spiral on the catalogue cover and in every store. But when I finally decided to make it about eight months ago, I found that after introducing a bunch of pastel colors in 2010, Ikea had all but discontinued colored Lack, leaving just red, white and black, and just a couple of wood “effect” finishes. [Seriously “birch effect” is such a sad concept.]

I had some pieces that I’d stashed or stored: a navy blue shelf, dark grey and dark green side tables, and either dumped or gave away a while ago because seriously, it’s Ikea. Just go get another one. But it’s precisely this misplaced belief that it’ll always be there that tripped me up. Ikea IS always full, and it DOES always look and feel the same in its way, but the specific products, even the iconic ones, are constantly in flux.

There were hints, warning signs, which I chose to ignore. A Lack side table was always ridiculously, disposably cheap: $12 or something. But in 2010, Ikea began value engineering them, eliminating packaging, and tweaking the materials a bit, to get the price even lower. For a while, they were $5.99. Now I think they’re $7.99. Rationalizing inventory and SKUs was obviously part of this ongoing, profit-wringing process.

And that brings up the implications of Ikea’s product choice winnowing, which are thoroughly depressing, yet fascinating. I’ve been scanning craigslist for months, trying to find any colorful Lack pieces. I’ve missed a couple in New York because I couldn’t get them in time, and I found one pink table in Alexandria, Virginia. But otherwise, the craigslist selection is relentlessly constrained: it’s almost entirely these fake wood finishes. And I can’t tell what came first: Ikea’s eliminating all color from their lowest-end table offerings, or the [$5 table-offloading] public’s total embrace of printed plastic that simulates [and poorly] actual wood.

The greatest/saddest listing I saw was from an American University student, who described his Lack side table as, “exactly the same table that everyone else has.” And it’s becoming even more so every day.

So anyway, if you have a lead on some colorful Lack side tables or hanging shelves [medium or small], definitely drop a line. Because I’m definitely buying.

Tag: Mari X IKEA

Enzo Mari X IKEA + 6-Year-Old =

So I guess you could argue–and you wouldn’t be completely wrong–that no matter how many coats of hand-rubbed varnish it has, no matter how carefully calculated its design, or how flush its finishing nails, how stainless its many steel screws, a dining table which a six-year-old girl can snap apart like a pair of ramen truck chopsticks cannot, in the end, truly be considered a success.

But anyway, it’s not worth arguing, because that’s what happened the other day. And it’s not important or even relevant to discuss exactly how it happened, or who did it. Because obviously, it’s my fault. In fact, if the Enzo Mari X IKEA autoprogettazione table survived a day in our house, it’s only because our family and regular visitors were living in fear, subjected to a constant, low-level psy ops campaign of tense looks and warnings, with suspected leaners getting regularly guided toward the table’s side seats and away from the cantilevered ends.

Because the top clearly broke on Ikea’s butt joint, and not my own is of little comfort; it broke where the fulcrum was–the base. I knew it would/could happen when I decided to make my table top from horizontally built up Ivar shelving instead of the other two options I had: 1) tracking down the original, 200cm long Ivar shelves that had just been discontinued when construction began, or 2) using the thick, pine slab head and footboards from a king-size Mandal bed. The former, I nixed because I decided that building a table from discontinued Ikea parts might hinder the vast revolution in autoprogettazione-inspired Ikea hacking that would surely follow the debut of my project. The latter, well, the bed frame came already finished, and that felt a little like cheating.

Now, of course, with a card-table sized dining table, I’m more than ready to compromise. But Ivar long shelves are still discontinued, and now, it turns out, so is the wood-intensive Mandal bed, which has been redesigned to use no headboard, or a weird, slatty thing you mount on the wall.

That means I’m going to need to re-create the table top as-is, and reinforce it underneath, and hope that it holds. Or I’ll replace it entirely, probably with some slabs of sick, slick, ultra-deluxe 500-year-old sinker pine from the bottom of some icy river somewhere. Either way, I’ll be back in the basement, varnishing something soon.

Previously: The making of an Ikea X Enzo Mari table, in many chapters

Non Realizzate: Proposta Per Un’Auraprogettazione

Apex Art just announced that Courtenay Finn and Gary Fogelson were selected for this year’s open curating slots. Finn’s proposal uses a work by Bruce Nauman as a jumping off point for a show about “the role of reading in artistic practice.” Fogelson’s will tell the incredible-sounding history of alternative, arts, and experimental filmmaking shown in the 1970s on Boston’s WBBI TV. Congratulations to both of them, and get cracking, time’s a wastin’!

I’d had an idea for a show percolating for a while, so I submitted it. As I re-read it now, it’s fascinating how much of it is stuff I’ve blogged about over the last couple of years. In a real sense, the blogging process was central to the development and coalescence of the show’s ideas, if not for the actual proposal, which I wrote up and submitted anonymously, as Apex Art requires.

It tied for 45th place out of 320 entries. 86th percentile, which is alright, I guess, in a B-show kind of way.

Anyway, it was inspired, as the title suggests, by Enzo Mari. It challenges the common conception of aura by applying Mari’s autoprogettazione reproduction strategy to instructions-based art practice.

And because it also includes references to the great gatherer of Unrealized Projects, Hans Ulrich Obrist, I thought I’d go ahead and share my proposal here. If you’re one of the 40 international, anonymous judges who rated it less than 4/5, I do hope you’ll drop me a line and tell me what might have improved it for you.

Many thanks to those folks who gave me feedback and art historical suggestions on the idea as I was putting it together, too. I don’t want to sound namedroppy–until we polish this bad boy up and put on this jargon-laden, Stingelpainting party somewhere else, then I’ll be thanking you often and loudly, I’m sure.

Proposta per un’auraprogettazione

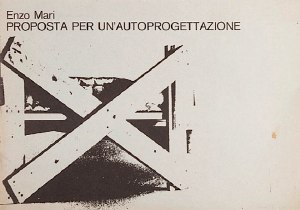

A project for making easy-to-assemble furniture using rough boards and nails. An elementary technique to teach anyone to look at present production with a critical eye. (Anyone, apart from factories and traders, can use these designs to make them by themselves. The author hopes the idea will last into the future and asks those who build the furniture, and in particular, variations of it, to send photos to his studio…) – Enzo Mari, Proposta per un’autoprogettazione, Duchamp Center, Bologna, April 1974

Walter Benjamin’s concept of aura is commonly understood as a quality that distinguishes an original art object from its mechanical reproduction. Recent alternative readings [Samuel Weber, 1996], particularly of cinema–Benjamin’s archetypal medium of modernity–consider aura as something not lost in (re)production, but instead contingent upon it. Aura is generated through contextualized reception via dispersed, multiple ‘originals,’ as literary or musical aura is transmitted via books and scores.

When coupled with Benjamin’s functional reconfiguration of the distinction between author and reader [“through a highly specialized work process…the reader gains access to authorship”], production of an auratic artwork at a [spatial/temporal] remove from the artist herself becomes feasible. The instruction performs such a distancing function.

From Moholy-Nagy through Lewitt, artists have used instructions and plans to challenge the privileging of gesture and authorship. The emergence of Conceptual art saw the concurrent normalization of instruction-based practice and the “dematerialization of the art object” [Lucy Lippard, 1973].

Lippard’s own seminal exhibition 557,087 (Seattle, 1969) was executed remotely using artists’ instructions, which comprised the show’s catalogue. Similarly, Do It (1993-) an ongoing exhibition/archive by Hans-Ulrich Obrist, solicits, executes and disseminates instructions from contemporary artists. [“With Do It in hand, you will be able to make a work of (someone else’s) art yourself.”]

Despite their critique of object/market complicity, instructions are regularly sublimated by capitalist constructs [i.e., editioning, certificates of authenticity] that reassert control and facilitate commodification.

Authorization thus emerges as a crucial and highly contested point of inflection/exchange for instruction-based work. Only five of 168+ instructions in Do It generate objects. One, a Felix Gonzalez-Torres candy pour (1994), was problematized when the artist’s catalogue raisonné [Cantje, 1997] reclassified it as “non-work” and reconfigured fabrication authority only for Do It‘s curators, not its audience.

A more conceptually robust corollary is art that applies a model exemplified by the Italian designer Enzo Mari, whose 1974 exhibition/catalogue, Proposta per un’autoprogettazione, (Proposal for a self-project) included not just blueprints for making 16 pieces of furniture, but explicit authorization to do so.

Mari’s autoprogettazione structure synthesizes Benjamin’s potential for multiple, auratic originals with the critical empowerment of readers-qua-authors, consumers-qua-producers, viewers-qua-artists.

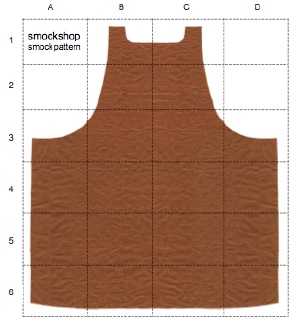

Auraprogettazione will be the first ever survey of this distinctive, exceptional genre: auratic objects, fabricated by whomever, in accordance with artists’ published instructions and authorization. Preliminary research has identified consonant works–painting, sculpture, photography, assemblage, clothing–by at least eleven artists: Daniel Buren, Jan Dibbets, Stephen Kaltenbach, Lia Maisonnave/Ciclo de Arte Experimental, Yoko Ono, Tobias Rehberger, Rudolf Stingel, Joep van Lieshout, Franz West, Zhuang Da, and Andrea Zittel.

Alongside the ‘originals’ exhibition, the gallery may be activated as a site of open, facilitated art production, or as an aggregator/repository of audience-made originals. Additional artists may be solicited to create new, permissioned, instruction-based work. And as with Mari’s original, Auraprogettazione‘s publications in print and online will propagate instructions for the exhibited works.

Enzo Mari X IKEA Mashup, Ch. Last

home stretch, from Thanksgiving 2007 to Thanksgiving 2009.

And it is done. [more pictures here]

A quick recap:

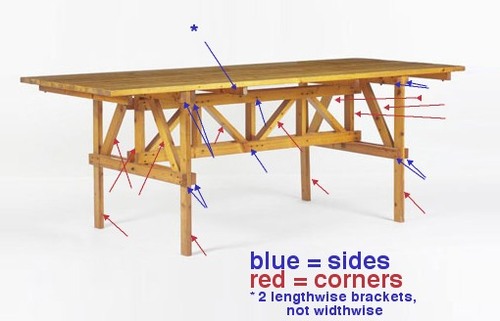

An EFFE table based on a 1974 design by Enzo Mari, but made entirely from unfinished pine components of Ikea’s Ivar shelving system. The vertical and diagonal elements are the square corner posts. [Some revisions were made mid-construction.] Horizontal elements are the pre-assembled shelving side trusses. [The center truss uses two trusses intact, while the end trusses use disassembled pieces.] The top is glued up from four Ivar shelves, which are braced underneath. [compare to Mari’s original design below.]

Though Enzo Mari’s original design calls for the low-grade pine to remain untreated, I decided to finish the entire thing with Sutherland Welles tung oil varnish. Components received five coats of wiping varnish, with sanding in between, before the trusses were constructed [finishing nails and #10 stainless screws]. The trusses and top then received six more coats of medium lustre varnish. The top will get two more, then a final sanding with steel wool.

Not only did the varnish cost more than the wood, all this hand-finishing turns out to be an insane amount of time and effort. Even so, the incredibly uneven quality of the Ikea pine resists a fine finish. This top may be conceptually ideal, but a more practical solution may be required if we decide to use the table daily.

Previously:

Autoprogetazzione: The Making of an Enzo Mari dining room table

Ch. 1: Enzo Mari x Ikea Mashup

Ch. 2: Parts

Ch. 3: Decisions, Decisions, adapting Mari’s design for Ikea lumber

Ch. 4: Finish Fetish

Ch. 5: In Process (Rev.)

Ch. 6: Ikeaness

Enzo Mari x Ikea Mashup, Being Mashed Up

ikea x Mari mashup being mashed up, originally uploaded by gregorg.

I realized I’d been putting off the actual assembly of my Enzo Mari table, daunted by the impending exactitude and fearful of the commitment of actually screwing all the pieces together.

Which seems to fly in the face of Mari’s original “just hammer it together” intentions for the autoprogettazione series.

I knew that without jigs and a flat surface and proper squaring equipment and such, I was invariably going to misdrill something, and then I’d be trying to redrill holes 1/8th of an inch to the left somewhere, and–

The joint that really made me nervous was the first one I’d have to do, drilling a 5/16″ hold through the center of all the side truss pieces [right about where the knot is in this photo] AND through the ends of the center truss, so that I could thread a carriage bolt through, and hold the entire table together properly. Forever.

Rather than risk screwing this up, I decided to piece each truss together with a steel bookend, and then hammer and wood glue enough joints to hold it. Then I’ll drill and screw the major joints after it’s together.

The carriage bolt and wingnut assembly method is a nod to the original autoprogettazione kits of precut wood, which were produced in 1973 by Simon International and sold briefly as the Metamobile Series.

I hadn’t thought of how much those simple wingnuts changed the nature of the autoprogettazione concept. They’re the difference between project and product.

The Metamobile kits weren’t just precut wood; they were also predrilled. And that required the construction of jigs, the use of some workshop- or factory-grade hardware, and probably even an assembly line, or at least some batch work. In other words, they were exactly what the autoprogettazione series was supposed to not be: mass produced.

Furniture sold as a kit of parts that comes ready to assemble, with just one tool, just follow the slightly baffling instruction diagrams exactly, and voila! Sound familiar? Enzo Mari beat me to an Ikea mashup by about 35 years.

Related: 14 June 2000, Lot 103: ENZO MARI, A PINE DINING TABLE

“designed 1973, manufactured by Simon International for the Metamobile Series, the square slatted top on open understructure secured by wing-nuts”, sold for £5,875. [christies.com]

Dec 15, 2006, Lot 2: ENZO MARI, AN EXTREMELY RARE “EFFE” TABLE

“Manufactured by Simon International, ca. 1974. from the Metamobile series…Acquired directly from Dino Gavina, c. 1975,” sold for $14,400 [sothebys.com]

Enzo Mari, PROPOSTA PER &c., &c.

Résultats de la vente 1567, Livres et manuscrits modernes, Lot 73, Enzo Mari PROPOSTA PER UN AUTOPROGETTAZIONE Milan, Galleria Milano, 1974. Cat. in-16 à litalienne, Vendu EUR 497 [artcurial.com]

Enzo Mari x Ikea Mashup, Ch. 5: In Process [Rev.]

An update on the Enzo Mari x Ikea autoprogettazione table project:

I just finished putting on the second coat of varnish sealer, and now everything’s drying and curing in the basement. The picture above was how the wood sat for a week between the first coat and this morning, stacked on our radiator [I moved it up after about 24 hours when it wasn’t quite cured, and then my schedule got away from me for the week.]

Continue reading “Enzo Mari x Ikea Mashup, Ch. 5: In Process [Rev.]”

Enzo Mari x Ikea Mashup, Ch. 4: Finish Fetish

For the 2002 reissue of his 1974 catalogue, PROPOSTA PER UN’AUTOPROGETTAZIONE , Enzo Mari added “a few technical hints.” I love them, especially the quotation marks, even as I prepare to ignore them a little and end up with something less “belle” than it could be:

…Then, from a purely formal (symbolic) and “instructive” point of view, table tops are “attractive” [“belle”] if they are made by putting several small planks together. From a strictly utilitarian point of view you can use plywood or chipboard.

For the same reasons the constructions are “attractive” if they are left rough, with the saw marks, neither planed nor varnished.

I found this slightly obsessive discussion of finishing solid pine furniture to be quite helpful, if a little daunting. But already, it saved me from myself and helped me lift my wood finishing sights beyond the lying corporate shelves of Ace Hardware:

First, however, a warning is needed: there is zero ‘truth in advertising’ in the finish industry. Absolutely anything can contain absolutely anything, no matter what the label says. There are products out there labelled tung oil that don’t have any tung oil whatsoever in them. Many ‘tung oil’ products depend mostly on phenolic resins. You have to buy from a source that is expert enough to know precisely what is in their products and trustworthy enough to tell you. In Canada, that’s Lee Valley, in the USA, Sutherland Welles.

Sounds good to me.

Sure enough, the extremely helpful folks at Sutherland and Welles guided me toward the right product for the project, a table with a top that will see regular use. I expect I’ll have enough polymerized tung oil varnish and sealer to give the table a good five coats, if not the 10-12 that Sankey prefers.

Meanwhile, I mapped out each piece to be cut onto the Ivar shelf components with blue tape. I plan to cut everything to length, finish the parts while I can reach all the corners, and then assemble the table. And then give it a last coat or two for good measure.

The wood cost $120, the tung oil, $82.

Enzo Mari x Ikea Mashup, Ch. 3: Decisions, Decisions

So I’m finally going to make my Enzo Mari autoprogettazione table from Ikea components. A publicist from Ford had offered a Flex station wagon for a road trip, and last weekend, I took them up on it. Which meant I could bring back the 89-in pieces of wood I’d scoped out. So I did. Next I will cut and finish the pieces. Then I will assemble the table.

Continue reading “Enzo Mari x Ikea Mashup, Ch. 3: Decisions, Decisions”

Enzo Mari x Ikea Mashup, Ch. 2: Parts

In the early 1970’s, Enzo Mari suggested using 1-by pine lumber to make his autoprogettazione furniture because it was cheap, standardized, easy to cut, and universally available at the corner hardware store. Now, my local hardware is a Home Depot, and the boards they sell come from New Zealand. So in keeping with the spirit of Mari’s design, I’m going to use components from Ikea furniture kits instead.

The dining table I’m going to make is called either F or EFFE, depending on which plans you look at [Mari’s own autoprogettazione book uses the former; Peter Stamberg’s 1976 blueprint anthology, Instant Furniture, which reproduces four of Mari’s autoprogettazione designs, uses the latter.] It calls for wood in two sizes. The truss and leg structure is made of 1×2 in lengths ranging from 10 1/2″ to 51″. The top calls for four 79-inch 1×8 planks, which actually comes to about 30″ across. [After it’s dried and finished, 1×8 boards are usually 3/4″ x 7 1/2″. I had no idea.]

There turns out to be far fewer useful sources of lumber in Ikea than I originally thought. [The idea hit me when I passed giant warehouse shelves filled with rolled up pine bed slats.] But most of the pine pieces in Ikea furniture are only 1/2-inch thick, too thin to use for underpinning a table.

Though I stuck to pine on principle, there is some solid wood furniture, mostly birch, with some oak. But by far, most of the wood-looking furniture is made from veneered particleboard; who knows what’d happen if you cut it?

I don’t doubt you could make a quintessentially Ikea Mari table by using only these kinds of components; the sleek, plastic-over-sawdust goodness of Ikea’s signature Lack tables and shelves could make for a very conceptually tight mashup, but that’d be the second or third piece I’d make, not the first.

The other major constraint is the length of the boards for the top; only three products have decent width pine boards within range of 79 inches [which is 200cm, if you’re wondering why Mari picked that length]. The 5/8-in. thick sides of the tallest Trofast storage units [above] are either 11 3/4 in. or 17 in. deep, but only 69 in. tall. And some of them have regularly spaced grooves for sliding bins.

[Though it felt like cheating, I did check out readymade tabletops. The Vika Furuskog tabletop comes in pine, and is 78 3/4 in. long, but only 23 5/8 in. wide; too narrow to use, too wide to double up on.]

The new Mandal bed [king-size, $249] comes really close to being the perfect Mari table kit. It has a smoothly sealed headboard and footboard of solid pine, which, on the king size model, are each 78 in. long. The headboard is 23 1/2″ wide, and the footboard is 12″; placed top-to-top, they’d be 35 1/2″ wide, which isn’t too far off. As a bonus, they have both taper on the bottom edge, which would be nice on the underside of the tabletop. [There is a row of pre-drilled holes along the base of each piece, though, which kind of bugs.]

Mari’s table calls for more than 66 linear feet of 1×2 wood underneath. It’s close, but the Mandal’s inner support rails may provide enough wood without buying extra pieces. The siderails are smoothly finished, too, and each 78 in. piece is 3 in. wide on the outside face, tapering to 2 in. wide on the inside face. The unfinished pieces underneath the bed are either 7/8 x 1 3/4 in. [i.e., 1×2], or 1 3/4 square. Four 1 3/4 sq. pieces are 27 1/2 inches long, just 1/4-in. longer than the table leg specs. If more wood is needed, a $20, twin-sized Sultan Lade bed slat offers one of the best options for raw wood. The 15 slats are 2 3/4 x 3/4 x 38, with slightly beveled top corners.

The Mandal has the added benefit of being factory sealed with a smooth acrylic finish. If it’s important to stick close to Mari’s original idea of unfinished wood, the far-and-away winner is the Ivar storage system. Ivar’s component-based, which means the shelves, side units, and corner posts may be all you need to make a table.

One pine top shelf [$19] is 3/4 x 11 3/4 x 82 5/8 inches Cut off the embedded metal brackets from each end, and it’s right at 79 inches. There’s also a vertical piece to cut off [or to not attach in the first place; the shelf I saw didn’t have it at all.] If you use three shelves, the table will be 35 1/4 inches wide, which adds 5+ inches to the horizontal pieces underneath the table, too.

Corner posts are 1 3/4-in. square and filled with drilled holes [$8, $12]. The side units are their own standard dimension–1 3/4 x 1 1/4 inches–which could be pulled apart and used as lumber. But it’s also tempting to use the ladder-like pieces whole. Both parts come in 70 1/4″ and 89″ lengths [$12, $15].

Maybe you could cut down [sic] on the sawing required by just making the table to Ivar’s dimensions instead of Mari’s. Then instead of a lengthwise shelf, you could build a top from shorter 33 x 11 3/4-in. shelves [$6] set crosswise.

I sit here trying to juggle the variables to the best effect: faithfulness to Mari’s original design; faithfulness to his concept, which is not quite the same thing; the inherent “Ikea-ness” of the inputs; the quality and utility of the output; the amount of tweaking, finishing, and labor required. And I repeatedly find myself creating a conceptual justification for the path of least resistance. All conceptual stunts being equal, I’m drawn toward the one that involves the least labor and mess. Which turns out not to be the same as requiring the least time, cost, or effort, as the 8-month over-analysis of making a simple table attests.

Enzo Mari x Ikea Mashup, Ch. 1

I wrote a few months ago about making a dining room table following Italian designer and theorist Enzo Mari’s 1974 Proposta per un’autoprogettazione, roughly translated as “A Project for self-design.” Mari’s goal was to effect a critical examination of the objects around us and the system of design, manufacture, distribution, marketing, and commerce that brings them into being. He did this by developing blueprints for a houseful of furniture that could be made from standardized pine lumber, in a day or two. The designs require only the simplest saw cuts and a hammer. And if you get the lumberyard to cut the lengths for you, it just requires a hammer. As Mari explained in an interview:

these items are not intended as alternatives to industrial ones, their creation is intended as a sort of critical exercise on design, and this is the reason why this experiment was called home design, not home production. The user, in repeating the operation, which can never be a slavish repetition…the designs have no measurements and while you are making them you can make changes, variations…when making the object the user becomes aware of the structural reasoning behind the object itself, therefore, subsequently he improves his own ability to assess the objects on the market with a more critical eye.

The EFFE table I want to build requires two sizes of board: 1×2 inch pine for the structure, and 1×8 planks for the top. In 1983, Mari explained that, “As regards material, the easiest to acquire is undoubtedly still the wooden plank.” Undoubtedly. So I headed down to the nearest hardware store, where there were several hundred varieties of curtain rod finials, but no lumber. I was told I could order pine boards of these dimensions, and they’d come in about a week. Couldn’t my contractor get wood for me? So I went to Home Depot, which had pine boards in several grades and dimensions. They were all from New Zealand.

First off, it wasn’t that nice-looking, but buying processed wood from the other side of the world in a 100,000-sf store seemed to contradict the spirit of the autoproggetazione project. Under those circumstances, Jeff Bezos’ critical response to the furniture design industry made more sense. [When he started Amazon, he made the desks out of hollow-core doors and sawhorses, a scrappy tradition the company continued.] But I didn’t want the aggressively cheap improvisation of a Bezos Table in my house.

The place where I saw the biggest piles of untreated pine lumber was, ironically, Ikea. The warehouse section near the store’s exit has palletsful of bookcases, chairs and beds, all flatpacked and ready for assembly [home production?] What would happen if you treat Ikea as your corner hardware store, and use their flatpack-optimized, mass-produced furniture components as the raw materials in an entirely different design?

Looking through the Ikea hacking communities, it seems no one had tried to make an Enzo Mari table from Ikea parts before. While Ikea publishes detailed dimensions for their assembled products, there’s no information on part specs. Over the course of several trips to Ikeas outside New York and Washington, DC, I identified every Ikea product that looked like a promising source of pine parts, and I measured each piece of wood.

Though there are many pine products at Ikea, there are just eight products or series whose parts come close to standard 1-by lumber dimensions. I’ll put them in the next post. Then I’ll calculate the various combinations to figure out things like the optimum use of material, the least amount of cutting, the cheapest/most expensive, the closest to Mari’s design, and the most successful table. We’ll see how it goes.

related: the 2002 reprint of Autoprogettazione from Corraini is much harder to find than it should be [abebooks]

previously: Autoprogettazione: The Making Of An Enzo Mari Dining Room Table

Autoprogettazione: The Making Of An Enzo Mari Dining Room Table

The economic and ecological and aesthetic far-sightedness of Enzo Mari’s 1974 Autoprogettazione still blows my mind. Translated variously as “self-projects,” and “self-design, self-made,” Mari’s collection of designs for furniture you could build yourself with just a hammer using cheap, off-the-shelf lumber anticipated several key design principles that resonate right now: DIY; sustainability; small-scale, local production and consumption; simplicity; handmade; hacking commercial products; and the open-source/creative commons movements [the furniture could be built by anyone except a factory or a dealer.]

Mari intended his Autoprogettazione to be made of #2 medium-grade, knotty pine, some of the humblest material on the market. He arranged for a company to pre-cut the lumber and sell it in packs as Metamobile. Naturally, one of these vintage 1974 kit tables sold for $14,400 at auction last fall.

Naturally, a gallery in Chelsea, Demisch Danant, just closed an exhibition of Metamobile furniture which they had made, and which they arranged for Mari himself to sign. Which seems to defeat several purposes of the entire Autoprogettazione concept, but that’s life.

I’m looking for photos of the first Metamobile furniture I saw, which is still my favorite: In 2004, Rirkrit Tiravanija produced Mari’s square dining table [above] and some chairs in chrome-plated stainless steel. The pieces weighed a ton, but they were truly spectacular, like Koons picnic furniture.

Anyway, we’re just in the middle of moving our place in DC, which gives me the occasion to need a bigger, nicer dining room table. Mid-century modernism is too relentlessly tasteful; recent prices of “good” furniture make me laugh out loud. Though I’m an unrepentant Ikea fan, it only goes so far [i.e., no serious furniture]. Mari’s furniture feels like the perfect counterpoint to the homogeneous mega-catalogue stores: C&B, Pottery Barn, CB2, West Elm, etc. etc. etc.

So I’m thinking of getting the Truss Table [top] known as the EFFE Table. As a city dweller, I’d have to have it made, or at least have the lumber cut and finished and delivered for my own assembly.

An ex-pat design firm in Japan used sugi, Japanese cedar, to make their EFFE table. For me, I think it’s key to use Mari’s intended pine. So far, I’ve sourced two wildly disparate, but potentially interesting woods:

update: Those Demisch Danant pieces appear related to a series of 18 pieces put up at auction last June in Paris. Artcurial has a making of video, though they don’t actually show what they made. An EFFE Table went for EUR2,231.